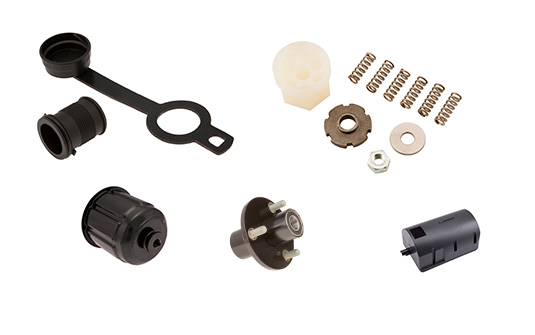

Discover Top-Quality OEM Equipment Parts for Every Industrial Demand

Discover Top-Quality OEM Equipment Parts for Every Industrial Demand

Blog Article

Leveraging OEM Construction Parts for Improved Resilience and Reliability in Your Jobs

Making Use Of Initial Devices Maker (OEM) construction components in your tasks can be a pivotal aspect in attaining enhanced sturdiness and integrity. The significance of picking OEM elements reverberates deeply in the construction market, where accuracy and top quality are paramount. By adhering to OEM specs, service providers and project managers can considerably boost the long life and efficiency of their frameworks. The benefits extend beyond mere functionality, including a realm where effectiveness and cost-effectiveness merge seamlessly. In a sector where every element adds to the success of a project, the reliance on OEM construction parts becomes a strategic choice that can elevate outcomes to unequaled degrees of quality.

The Relevance of OEM Building And Construction Parts

Utilizing OEM construction parts is crucial for making certain the top quality, dependability, and performance of building and construction tasks. Original Equipment Supplier (OEM) components are specifically designed and produced to meet the specific specs and standards established by the devices's original supplier. This makes sure compatibility and optimal operating within the machinery or framework, decreasing the danger of failures or breakdowns.

The significance of OEM construction components hinges on their premium high quality and accuracy engineering. These parts undergo extensive screening and adhere to rigorous high quality control measures, ensuring their resilience and long life. By utilizing OEM components, construction tasks can maintain the honesty of the devices, protecting against unnecessary damage that may arise from making use of substandard or incompatible parts.

Moreover, OEM parts usually come with guarantees and technological support from the maker, giving added assurance and tranquility of mind to task managers and building groups. This degree of assistance can be very useful in making sure prompt project completion and lessening downtime as a result of equipment problems. On the whole, the use of OEM building components is a basic element of attaining effective construction projects defined by performance, safety and security, and longevity.

Boosted Longevity With OEM Parts

To attain heightened long life and robustness in building and construction projects, the consolidation of OEM components is necessary. Original Devices Supplier (OEM) parts are particularly created and manufactured by the original manufacturer of the equipment or machinery, making sure compatibility and premium quality. Improved durability is an essential advantage of making use of OEM parts in building jobs. These parts are crafted to fulfill the exact specs and requirements of the initial tools, guaranteeing an exact fit and optimum efficiency. By utilizing OEM parts, building jobs can reduce the threat of early deterioration, malfunctions, and pricey repairs. OEM parts also go through rigorous screening to make certain integrity, long life, and durability, providing job managers and stakeholders assurance.

Moreover, OEM components typically come with service warranties, better improving their appeal in building and construction jobs. These warranties offer included protection and assurance, permitting for economical maintenance and substitutes if needed. Overall, the assimilation of OEM parts in building and construction jobs can significantly improve longevity, lessen downtime, and improve the general reliability of the frameworks or tools being used.

Making Certain Dependability in Your Tasks

Incorporating OEM components in construction jobs not only improves sturdiness yet likewise plays a crucial function in making certain reliability in your ventures. Integrity is an essential consider the success of any building task, as it directly affects the job's timeline, price, and overall performance. By utilizing OEM components, which are designed and checked by the initial tools manufacturer, you can reduce the danger of unexpected failings and make certain that your task runs smoothly from beginning to end.

OEM parts are produced to fulfill rigorous quality standards, guaranteeing uniformity and compatibility with the remainder of the devices or equipment. This compatibility decreases the possibility of malfunctions or breakdowns, causing raised uptime and performance for your task - Oem Construction Parts. In addition, OEM components often come with assurances or guarantees, offering you with added assurance of their reliability

Regular maintenance and timely substitute of damaged components with OEM elements even more add to the dependability of your building jobs. By prioritizing reliability via the usage of OEM components, you can reduce risks, minimize disruptions, and inevitably attain successful task end results.

Maximizing Performance With OEM Parts

Enhancing job effectiveness via the tactical release of OEM components is a keystone of making best use of efficiency in construction undertakings. OEM site web parts, made particularly for the equipment they are planned for, provide a level of accuracy and compatibility that aftermarket parts might not always assure. By using OEM components, building and construction projects can maximize efficiency in terms of integrity, longevity, and general functionality.

Making use of OEM components makes certain that each part fits flawlessly into the bigger building equipment, decreasing the threat of breakdowns or breakdowns. This compatibility likewise extends the life-span of the devices, as OEM parts are engineered to satisfy the finest criteria set by the initial equipment producer.

In addition, OEM components usually come with guarantees and technological support, offering added satisfaction to project supervisors and building groups. This support can be vital in decreasing downtime and guaranteeing that jobs remain on timetable and within budget. In general, enhancing efficiency with OEM parts is a strategic investment that can produce substantial long-term benefits for construction jobs.

Durability Advantages of OEM Components

One of the crucial benefits of OEM parts is their compatibility with the existing devices - Oem Construction Parts. By utilizing OEM parts, you can be positive that the parts will fit completely and operate seamlessly within the machinery. This best fit reduces deterioration on the tools, expanding its lifespan and lessening the threat of unexpected break downs or breakdowns

In addition, OEM components are manufactured using top notch products and stick to strict quality assurance requirements. This causes components that are more resistant to rust, abrasion, and other types of damages, inevitably adding to the longevity of the equipment.

Conclusion

To conclude, using OEM linked here building and construction components can significantly Find Out More enhance the resilience and dependability of your jobs. By making sure that you are making use of real components from the original tools manufacturer, you can maximize efficiency and expand the long life of your building and construction tasks (Oem Construction Parts). This dedication to high quality and authenticity will ultimately result in a more sustainable and successful construction procedure

Utilizing Original Tools Supplier (OEM) building and construction components in your jobs can be a critical factor in attaining enhanced toughness and dependability.Utilizing OEM construction components is important for ensuring the top quality, integrity, and efficiency of building tasks. By making use of OEM components, building projects can preserve the integrity of the tools, stopping unnecessary wear and tear that might result from utilizing substandard or incompatible components.

Overall, the usage of OEM construction components is an essential facet of accomplishing successful construction projects identified by safety and security, effectiveness, and longevity.

On the whole, the integration of OEM components in construction jobs can significantly improve resilience, minimize downtime, and boost the general reliability of the frameworks or tools being made use of.

Report this page